<

>

Engineering

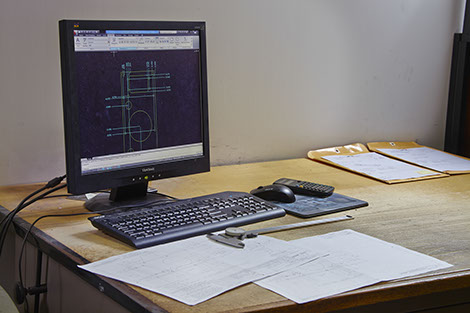

Aero Precision Engineering, Inc. specializes in custom precision sheet metal parts and assemblies, in addition to precision milled and turned components. Utilizing some of the newest cam software available, such as Mastercam X7 and Amada AP100, allows us to rapidly and precisely import your cad data for a seamless transition to our manufacturing floor.

Amada CNC Turret punch presses with 20 ton punching capacities with travel limits up to 50” x 50 “ accurately and quickly create sheet metal parts. A 2000 watt Amada Laser with travel limits of 50” x 50” can precisely create prototype or production parts without the need of hard tooling.

High speed CNC machining centers have 3, 4 and 5 axis configurations. As well as CNC turning centers with bar feeders can rapidly machine complex machined items. Additionally, a full complement of supporting equipment including forming, spot welding, welding, metal finishing, and assembly complete our manufacturing capability.

All internal and external processes from quoting to shipping are generated and monitored with an integrated E2 Shop Control software package. We also partner with a number of local plating and paint shops to enhance our value added services to our Aerospace, Defense, Computer, and electronic customers.

11300 Hindry Avenue, Los Angeles, CA 90045

Office: (310) 642-9747 Fax: (310) 642-9746